Quality Control Statement

- Teilen

DiZNEW Quality Control

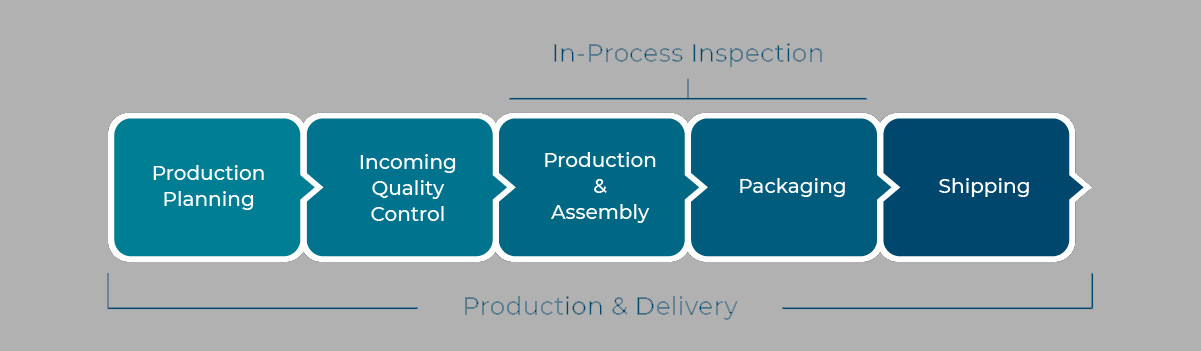

At DiZNEW, we understand the demanding quality requirements of high-end and luxury brands. Our commitment is to provide unparalleled denim products that meet the highest standards, especially for premium brands like Amiri. We have developed a comprehensive Quality Control system designed to ensure that every pair of jeans meets strict quality standards, from raw materials to finished products. Our Quality Control process consists of 8 key checkpoints, each ensuring top-tier craftsmanship and consistency throughout production.

1.Raw Material Inspection

Before production begins, we perform rigorous testing on all raw materials to ensure that every fabric and component meets international standards. Our fabrics are primarily sourced from local suppliers in China, which allows us to maintain competitive production costs while also adhering to sustainable practices. We can also purchase raw materials overseas according to the demands of our customers. We place a high emphasis on the environmental impact, colorfastness, tear resistance, and durability of the fabrics, ensuring they meet the demanding quality expectations of high-end brands.

2.Fabric Pre-treatment Inspection

Before the fabric enters the production phase, we conduct detailed pre-treatment inspections to ensure that color fastness, shrinkage rate, elasticity, and other key technical aspects meet high-end brand requirements. This step is crucial in preventing potential quality issues during later stages of production, such as fading or shrinking, guaranteeing the perfect finish of the final product.

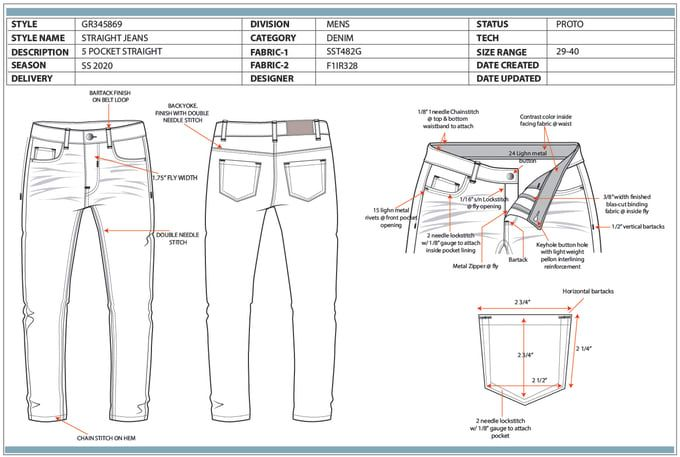

3.Sample Review

Before commencing full-scale production, we create precise samples for each design, which are then reviewed by the client’s design team. The sample review is not just a design verification, but also a comprehensive check of the fabric, craftsmanship, and details. We work closely with our clients to ensure that each product aligns with their brand’s unique specifications and market positioning.

4.First-Stage Production Check

In the early stages of production, we conduct a thorough inspection of the production line to ensure that the first batch of products adheres to expected quality standards in terms of craftsmanship, cutting, and detail handling. We focus on key aspects such as equipment stability, worker precision, and consistency of quality execution during the initial phase.

5.Mid-Production Check

Throughout the production process, we schedule regular mid-production inspections to assess both the quality and progress of production. This step allows us to detect any potential issues early on, ensuring prompt adjustments to prevent any impact on the final product’s quality. By meticulously monitoring each batch, we ensure consistency and maintain the highest standards across the entire production run.

6.Detail-Oriented Quality Check

During this phase, we conduct a thorough check on each product's finer details, including seam quality, zipper functionality, and button durability. We ensure that every pair of jeans reflects the meticulous craftsmanship that high-end luxury brands demand. We pay close attention to stitching precision and ensure that all hardware is securely attached and functional, ensuring no detail is overlooked.

7.Finished Product Inspection

Once the products are completed, we perform a comprehensive final inspection of each pair of jeans. This includes visual checks, dimensional measurements, and functionality tests. We ensure that every pair of jeans meets design specifications and quality standards. Special attention is given to ensure there are no defects, imperfections, or issues that might impact the product’s aesthetic or wearability.

8.Pre-shipment Final Inspection

Before shipment, a final quality inspection is conducted to ensure that all products meet the client’s specifications and are compliant with international certifications and quality standards. This inspection covers every aspect of the product, including appearance, functionality, and packaging, ensuring that every pair of jeans arrives in perfect condition.

Through this meticulous Quality Control process, Diznew ensures that each pair of jeans meets the highest standards expected by premium brands. Our focus extends beyond the appearance and craftsmanship. We pay close attention to every detail, ensuring that each product reflects the excellence demanded by high-end and luxury brands. Additionally, by localizing fabric sourcing and managing the production process with precision, we align with sustainable development goals, helping our clients achieve their green initiatives.

Our goal is to deliver impeccably crafted denim products for high-end and luxury markets, providing our clients with the quality and consistency they need to thrive in the global market.